| HOW

TO INSTALL THE MT19 REAR AXLE AND SPROCKET MODIFICATIONS

So, you

want to take one of those exotic trips in your MT19 but have heard

stories about rear axles breaking. The last thing you want is

to have your axle break halfway to Tumbler Ridge or in the

middle of the Copper Canyon. What to do?

Well,

in recent years several NARCOA members have researched the cases

of broken MT19 rear axles and determined that the original installation

design lead to excessive flexing of the axle under certain conditions,

which ultimately caused axle failure.

In an

effort to correct the problem, a second chain idler sprocket

was mounted on a redesigned bracket that eliminates much of the

excessive axle flexing by changing the path of the drive chain.

This modification is described in the Nov./Dec. 2000 SETOFF in

detail. We now produce this special bracket.

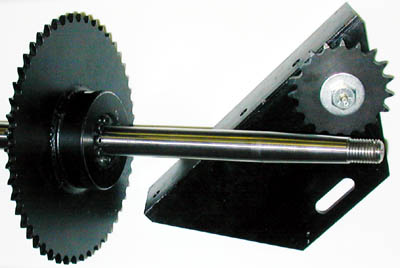

A new

rear axle made of 4150 HT turned, ground and polish steel which provides much more strength than the original

axle has recently become available. Since most axle failures

occurred at the keyway which is the weak point of the original

axle design, it has been eliminated by using a U.S. Tsubaki “PowerLock”

keyless sprocket. The details for the axle and sprocket were published

in the Mar./Apr 2001 SETOFF.

Anyone

contemplating a rear axle replacement should read both these

articles. A number of cars have been modified and have run long

distances during the 2001 season with no failures.

In order

to install the dual idler bracket, you will have to reverse the

center axle bearing so that the support bolts are behind the rear

axle. (A few later cars were built this way by Fairmont in an

apparent attempt to solve the breakage problem) You must remove

or at least partially remove the rear axle in order to reverse

the bearing block as just flipping it 180 degrees on the axle

will not work due to the shape of the casting. If you are going

to install the bracket, you might as well change the axle at the

same time, since the rear axle may be near the point of failure

and your going to do almost all the work anyway.

A few

special tools make the job much easier. You will need a

1-5/16” socket for the axle nuts. Probably the most difficult

part of an axle change is removing the wheel hubs from the axle.

Our hub puller works extremely well. It makes hub removal as easy

as removing a wheel. A turntable makes the job much easier by

allowing easy access under the car. Be sure the car is also blocked

in position so that it cannot fall on you before going underneath.

If you don’t have a turntable, you will need to find a way to

lift the car while leaving the rear wheels and axle free to turn.

A few

things to think about before beginning. Check the gauge of the

car by placing a tape measure through the “spoke” holes in the

wheels and measuring from wheel face to wheel face. Fairmont calls

for a dimension of 62-3/4” and cautions that the front and rear

axle should be the same. If the rear axle is under gauge, you

may want to change the insulators while you have the hubs off.

If the front is undergauge, and you don’t want to pull the hubs

to change the insulators, our shims can be ordered in 1/16” and

1/8” inch thicknesses to set the wheels to proper gauge and match

the rear wheel gauge.

Before

you lift the car from the ground, break the wheel nuts, axle nut

and the four Allen headed screws on the rear sprocket loose so

the can easily be turned. Like changing a tire on your car, it

is much easier to fight a seized nut on the ground. After

the car has been lifted, hopefully using a turntable, make sure

it cannot fall by blocking, jacking etc. as needed, then remove

the drive chain, both axle nuts and both wheels. Inspect the wheels

for flange wear and thickness. Measure the circumference of each

wheel. If the are not both nearly the same, you will have additional

axle forces due to the wheels trying to turn at different speeds

on a solid axle.

Next remove

the wheel hubs. Put the axle nuts back on the axle to protect

the thread and then install the hub puller. Most of the time,

the hubs will come off with very little problem. I have

had some that were really seized in place and when they finally

broke loose, they made a report like a rifle. Loosen the thrust

collars that hold the axle in position and slide them out of the

way. Use a small file to dress out the area where the thrust collar

set screw has made a mark in the axle.

Now disassemble

the two sprocket halves by removing the Allen screws and nuts.

Fairmont used two different types of sprocket hubs. The earlier

style had a bolt that pressed against the key in the axle. Removing

this bolt should break the hub free. Later hubs used a tapered

lock. If you have this style, note three bolt heads with two holes

that have no bolts. Remove the three bolts and thread two of them

into the holes that were not used and tighten. This will pull

the taper lock out and free the hub assembly. Remove the two bolts

that attach the center bearing to the frame. You should now have

everything loose on the axle.

The most

difficult part of the job may be cleaning the rear axle.

All paint, dirt, grease etc. must be removed as the axle will

have to slide out to one side or the other through the wheel bearing

which has a very close fit. Use sandpaper, emery cloth, Scotch

Bright Pads, paint stripper and what ever else is needed to be

sure the axle is as smooth and clean as new. Attempt to

slide the axle out one side. If it begins to bind, polish

out the area that is causing the problem and try again. The bearings

have a very close fit and the axle should not be forced when sliding

it out.

Okay,

you now have the axle and all components laying on the floor and

are nearly ready to install the new bracket. Remove the old idler

bracket assembly. You will reuse the same holes and hardware that

held the old bracket. Count the teeth on the original idler sprocket.

If it is a 17 tooth sprocket, you will need to get a 19 tooth

sprocket to match the one supplied in the kit. (The holes in the

bracket are for dual 19 tooth sprockets.) Inspect the condition

of the old idler sprocket as well as the forward sprocket on the

transmission. Check the teeth for wear, gouges, etc. Replace as

needed.

The new

dual idler bracket can now be installed. A section of the bracket

is milled out to accommodate the battery hold down nut. The bracket

has four mounting holes that align with the bolt locations for

the old idler bracket and center bearing when it was in the original

position. Be sure the bracket is exactly parallel with the car

frame and then tighten the nuts.

The original

Idler sprocket shaft used a special zerk style grease fitting

that was threaded in a very small hole in the shaft head. Our

new idler shafts are drilled and taped to 1/8” NPT for a standard

zerk fitting. Grease gun extension hoses, available in various

lengths at the local hardware store, can be threaded into this

shaft and passed through the car frame using a coupler and zerk

fitting on the outside of the car.

If you

do the same to the center bearing and all wheel bearings, you

will be able to grease the car without crawling underneath. You

will need to order a second idler shaft or have the original one

drilled and tapped for 1/8” NPT to attach the grease hose.

The top

sprocket may be installed and tightened using the lock washer

and nut provided in the kit. Install the lower sprocket, but do

not completely tighten yet as it must be moved to adjust chain

tension. I installed a flat washer under the lock washer to make

it easier to slide the sprocket in the elongated hole when adjusting

the chain.

Before

going any further, it would be a good idea to do a little inspecting.

Check the brake shaft in the area underneath the drive chain.

Many cars with loose chains will have damage to the brake shaft.

Do not operate the car if the shaft is damaged. Order a new one

or perform a proper repair on the old one but don’t let it go.

Any wear is unacceptable as it could lead to brake failure.

This next

step is optional and not required for the installation of the

axle or idler bracket, but since the axle is removed, it is much

easier to do now than it any other time. Check the springs. If

they are in poor shape. You will never get a better chance to

replace them. The same goes for the oilite guides which allow

the bearing casings to move vertically.

If you

decide to remove the springs or check the oilite guide bushings,

you must remove the bearing casings. To do so, you must drop the

aluminum channel (rail skid) that passes under both the front

and rear wheel bearing casings.

Remove

the two long bolts that pass through the guide tubes in the rear

bearing casing. Remove the two lower bolts that hold the rail

skid to the triangular shaped gusset plate just forward of the

rear axle as well as the bolts in the gusset plate just aft of

the front axle. Remove the single bolt that holds the brace to

the center of the rail skid. Now loosen, but do not remove the

nuts from the bolts that pass through the casing guide tubes on

the front axle. Don’t loosen them too much as you don’t

want the front axle to drop out of position. Do one side of the

car at a time. The rail skid should drop down enough to allow

the bearing casing and springs to be removed.

If you

open the bearing casings to check bearing condition, be careful

of the shims. Don’t loose any and make sure they go back in the

proper position. If you replace the bearings, shim them according

to Fairmonts instructions. If you need to replace the bearings

or the guides, you will have to heat the casing to get them out.

The rear springs are lighter duty than the front springs and are

not interchangeable. It is a good idea to order a set of four

of the special cylindrical nuts used to center the top of the

springs. These nuts break easily and are often replaced with improper

hardware in the field which can lead to spring failure. Reassemble

the bearing blocks and rail skids in the reverse order that they

were removed and properly tighten all hardware.

Assuming

everything is now in top condition, it is time to install the

new 4150 HT axle. Insert the axle through the bearing casing

and install in proper sequence, the thrust collars, center bearing

(turned 180 degrees from the original - the bearing cover bolts

will be on the left side) and the new “PowerLock” sprocket (Allen

screws should be facing to the right). Don’t tighten anything

yet. Do a runout on the axle to insure that it is perfectly straight

and is not being offset by a bent frame or mis-positioned bearing

casing. Drill two holes and mount the center bearing support.

I did not install the center bearing spring as my understanding

that Fairmont left them out in later cars as they were not needed.

After the center bearing is mounted, check the axle runout again

to be sure you got the center bearing properly positioned.

Before

tightening the thrust collars, make sure that exactly the same

amount of axle sticks through the bearing on each side of the

car. Tighten the thrust collar clamping bolt before tightening

the set screw. Don’t forget to safety wire the set screws Use

stainless steel wire if possible.

Carefully

position the new sprocket so that it is exactly aligned with the

forward sprocket on the transmission. The eight Allen headed

screws were gradually tightened in a crisscross pattern and then

torqued them to 12.3 foot pounds. A paint stripe applied to the

“PowerLock” and axle can be used to detect any slippage.

See the instructions and illustrations below for more information.

Since

the path for the chain is now slightly longer, I found that I

needed to add two rollers for the chain to be long enough. Start

by counting the number of rollers in your old chain. (Mine had

130) Install the old chain with the lower sprocket slid all the

way aft. Position the chain so that the masterlink would go on

the aft part of the axle sprocket and pull it as tight as possible.

With both ends of the chain on the axle sprocket, you can easily

count the number of links that need to be added.

It is

not a good idea to reuse an old chain or to add links to an existing

chain, instead, just order a new one with the proper number of

rollers and a new master link. Chains can only be cut with an

even number of rollers, so if you need three instead of two, order

an offset link. If you must cut the chain, pick up a chain cutting

tool from a local bicycle or motorcycle shop. These tools are

inexpensive and will keep you from damaging a new chain if it

is too long and needs to have links removed.

The SETOFF

article indicates that the chain in this installation should be

somewhat tighter than originally installed since the chain path

length is more constant due to the geometry of the added sprocket.

I found that if I tightened the chain until taught with the weight

of the car off the wheels, with the car on the ground, the tension

slackened slightly and seemed to me to be about right.

Check

the condition of the chain whip guard blocks. If they are worn,

new blocks and or brackets should be ordered. Reposition them

as needed for the new chain location.

Reinstall

the wheel hubs and snug them sufficiently to keep them secure.

You can fully tighten them once the car is on the ground. Don’t

forget to put the phenolic insulator washer against the hub and

the metal washer under the nut or you will be setting off every

grade crossing you pass!

Check

the condition of the wheel attachment hardware, replace as needed

and reinstall the wheels. Lower the car to the ground and

tighten the axle nuts. Install new cotter keys. Tighten all wheel

nuts and check the gauge is you did before starting. Check that

the wheels have equal distance between the inside of the flange

and the car frame. Recheck chain tension and reinspect all work

to be sure nothing has been missed.

Your car

rear axle and suspension should now be in top shape and ready

for many years of happy motoring without problems. After

a few hours of operation, recheck the torque on the PowerLock

screws. Do it again at the end of the season.

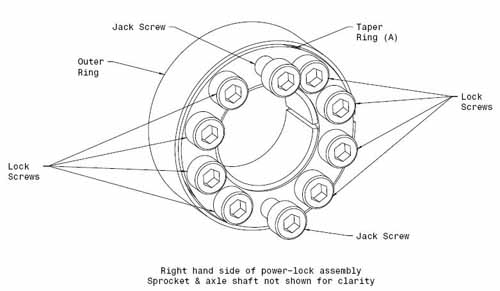

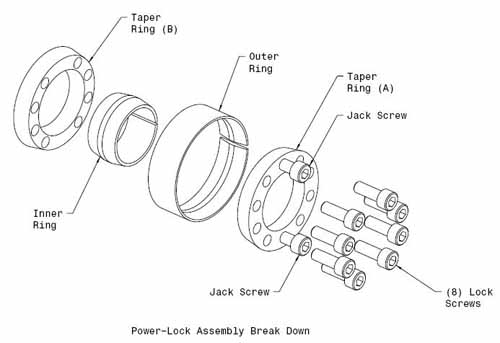

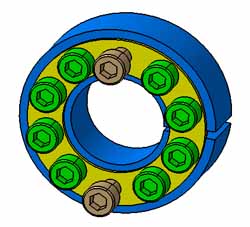

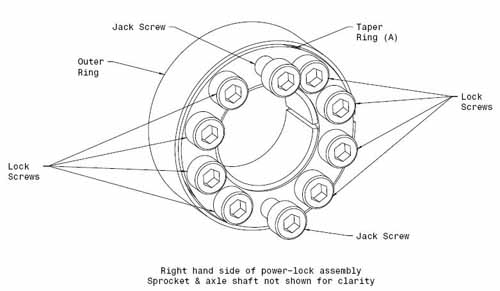

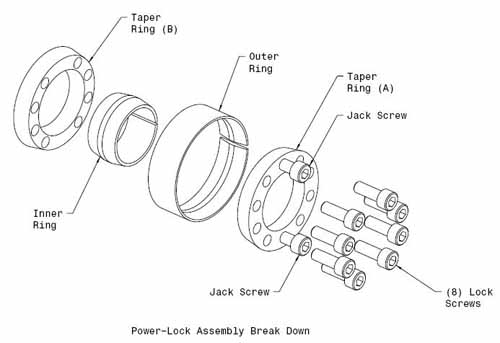

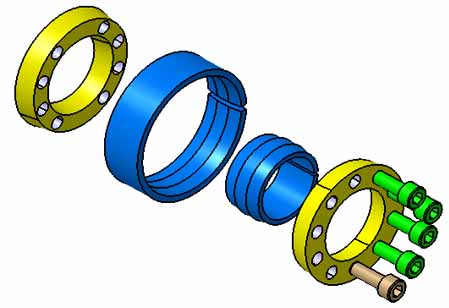

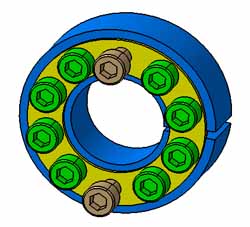

"Power Lock" Mounting and Removal

The

POWER-LOCKŪ is composed of five parts: taper ring (A), taper ring (B),

outer ring, inner ring, and locking screws. Locking is achieved by

tightening the screws.

|

|

Mounting

1) Clean and lightly oil or grease the shaft and

hub bore. (Do not use oil or grease containing molybdenum disulphide.)

2) Remove the locking bolts from the POWER-LOCKŪ

and clean and lightly oil, or grease the contact surfaces. Threads and

seats of the locking screws must also be sufficiently lubricated.

3) Slip the POWER-LOCK and hub onto the shaft,

tighten the locking screws by hand until a slight positive contact is

felt, and set them at the predetermined position, just as you would

tighten lug bolts on a car wheel. When it is difficult to slip on,

loosen the screws. (Do not strike with a hammer.)

4) Next, determine the relative positioning

between the hub and shaft (on the circumference and shaft line), and

tighten the four screws positioned diagonally with 1/4 of the required

tightening torque. Proceed to tighten the remaining screws in the same

manner.

5) Increase the tightening torque to half of 12.3

foot pounds and tighten the screws in the same way as in Step 4.

6) Increase tightening torque to 12.3 foot pounds and tighten the screws.

7) Check the tightening torque of the locking screws in sequence. This completes the mounting procedure

NOTE:

There are ten holes in taper ring (A) with eight of them being lock

screws The other two are jack screws. The jack screws are only

required for removal of the power-lock hub either by pulling on the

heads or turning them in against inner taper ring (B). |

|

Removal

1) Make sure that no torque or thrust is being

applied to the shaft and hub. When shaft and hub are heavy, take them

off the shaft carefully.

2) After completing Step 1, loosen the locking screws. (No definite sequence is required.)

3) If the POWER-LOCK is still locked even after

loosening the screws, insert screws into the jack screw holes (see photo

below) and screw them in until it unlocks.

|

|

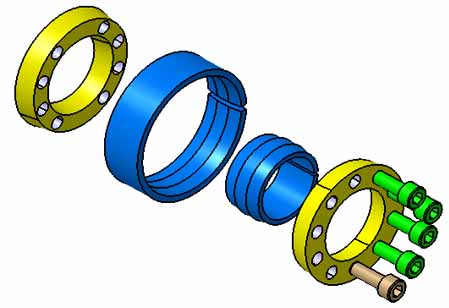

The drawings at left are courtesy of Wayne Schlueter and Illustrate in color the Power-Lock Assembly.

Thanks, Wayne. |

|

|

|